Tons of green petroleum coke arrive every day from the refineries at our industrial unit, located in Cubatão, São Paulo.

Production Process

From green petroleum coke, our basic raw material, we produce calcined petroleum coke with low sulfur and metal content and with excellent physical-chemical properties, serving the most demanding customers in the market. We are the only producer of anode grade calcined coke in Brazil, used in some of the leading aluminum industries in Brazil and the world.

Far more than processing petroleum to produce calcined petroleum coke, Petrocoque guarantees a sustainable production process.

-

Step 01

Step 01 -

Step 02

Step 02The green petroleum coke is ground to adjust particle size and then stored in a covered patio.

-

Step 03

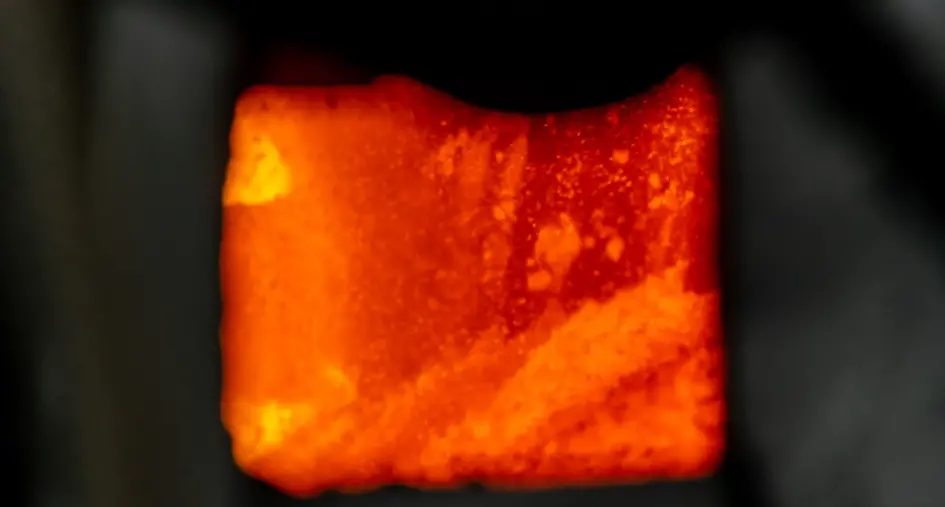

Step 03The green petroleum coke is transported from the patio to the calcining ovens, where it is transformed into calcined petroleum coke at high temperatures.

-

Step 04

Step 04Then the calcined petroleum coke is cooled and stored in silos and/or covered shed. It is then transported to the main consumer market, the aluminum market.

-

Step 05

Step 05During the transformation from green petroleum coke to calcined petroleum coke, a large amount of thermal energy is generated, which is used for the generation of water vapor and electricity, keeping Petrocoque self-sufficient in electrical energy generation. Surplus electricity and steam are sold, keeping the process highly sustainable.